Spark Ignitors

Showing all 25 resultsSorted by popularity

- Sale!

Worcester Bosch Electrode kit 8716121817 – New

Original price was: £44.99.£24.99Current price is: £24.99. Add to basket - Sale!

Ideal 175593 Ignitor Unit (Pre ADP) – Spare for Ideal Logic, Morco,Keston Models

Original price was: £29.99.£20.90Current price is: £20.90. Add to basket - Sale!

Ideal ISar/Esprit/Icos Spark Generator 173538

Original price was: £34.99.£29.99Current price is: £29.99. Add to basket - Sale!

Ideal 178205 Ignitor Unit Clip On (ADP Onwards) – Genuine Ideal Boiler Igniter

Original price was: £49.99.£42.99Current price is: £42.99. Add to basket - Sale!

Worcester Greenstar CDI & COMBI Temperature Limit Stat 87229638580

Original price was: £19.99.£18.99Current price is: £18.99. Add to basket - Sale!

Spark Ignitor for Baxi Combi 5114766

Original price was: £9.49.£8.99Current price is: £8.99. Add to basket - Sale!

Main Boiler Spark Ignitor 5114766

Original price was: £8.99.£8.54Current price is: £8.54. Add to basket - Sale!

Potterton Promax Spark Ignitor 5114766

Original price was: £9.49.£8.99Current price is: £8.99. Add to basket - Sale!

Glowworm 24CXI 30CXI 38CXI Flow Sensor 2000801910 S5720200

Original price was: £34.99.£27.99Current price is: £27.99. Add to basket - Sale!

Remeha Transformer Ignition 720481501 S62750

Original price was: £20.99.£15.89Current price is: £15.89. Add to basket - Sale!

Vokera Linea Plus AG Ignition PCB 10021848

Original price was: £39.99.£34.99Current price is: £34.99. Add to basket - Sale!

Worcester 87186880150 Transformer Ignition- fits Compact & Greenstar CDI, SI, RI, i System models

Original price was: £25.00.£23.75Current price is: £23.75. Add to basket - Sale!

Ideal 173538 Spark Generator – Brand New

Original price was: £69.99.£62.99Current price is: £62.99. Add to basket - Sale!

Intergas Smart Ignition Module Sie 801537

Original price was: £24.99.£19.99Current price is: £19.99. Read more - Sale!

Baxi Igniter 248097

Original price was: £14.90.£12.90Current price is: £12.90. Add to basket - Sale!

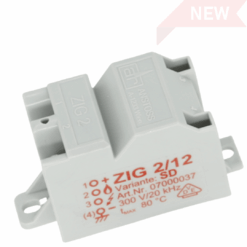

Glow-worm 801655 ZIG Ignitor – Spark Generator for CXI, HXI & Ultracom Boilers

Original price was: £44.99.£29.99Current price is: £29.99. Add to basket - Sale!

ATAG Boiler Ignitor Replacement S4744100

Original price was: £79.99.£44.99Current price is: £44.99. Add to basket - Sale!

Vokera Linea HE Spark generator MPN 15900001

Original price was: £24.99.£23.74Current price is: £23.74. Read more - Sale!

Remeha S62750 Ignition Transformer (Replaces 720481501)

Original price was: £35.00.£24.80Current price is: £24.80. Add to basket - Sale!

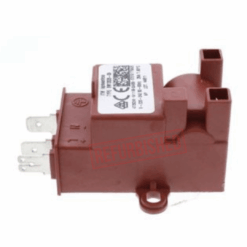

Glow-worm 0020020763 Igniter – Spark Ignition for Flexicom & BG Boilers

Original price was: £49.99.£29.99Current price is: £29.99. Add to basket - Sale!

Fenwal 35-630200-007 control pcb automatic spark ignitor

Original price was: £149.99.£107.99Current price is: £107.99. Select options This product has multiple variants. The options may be chosen on the product page - Sale!

Heatline Monza 24C spark igniter 0020111021

Original price was: £14.99.£14.24Current price is: £14.24. Add to basket - Sale!

Vaillant 091258 Spark Generator – Ignition Unit for Vaillant Boilers

Original price was: £49.99.£25.00Current price is: £25.00. Add to basket - Sale!

Vaillant 0020213915 Spark Generator – Ignition Unit for Sustain & ecoTEC Boilers

Original price was: £20.99.£14.99Current price is: £14.99. Add to basket - Sale!

Worcester 8716117684 Ignition Transformer for Compact & Greenstar Boilers

Original price was: £29.99.£18.90Current price is: £18.90. Add to basket